Titanium Melting Shop

TiFast has three new melting furnaces to produce titanium ingots. Two of them use the Skull Melting Technology and the last one is a VAR (Vacuum Arc Remelt). These three furnaces use an under-vacuum melting process by electrical arc.

The Skull Melting technology has several advantages. Firstly, it is considered the best one to reach a high chemical homogeneity, due to the fact that the metal under melting is mixed for a long time inside a crucible.

As a second advantage, Skull Melting is a cold hearth technology that removes both low (hard alpha) and high density inclusions. It is the best method to produce clean titanium.

A third advantage is that Skull Melting technology is economical: all the titanium melting technologies melt a mix of titanium sponge and recycled titanium material but the Skull Melting technology allows to use a higher quantity of recycled scrap.

The new VAR melting furnace, a standard in industry, can allow multiple meltings, including the remelting of Skull melted ingots. Such new and flexible production route has a bright future and it is already used in Medical, Racing and Aerospace applications.

TiFast can melt a full range of titanium alloys, as well as zirconium and nickel alloys. TiFast can supply ingots in a full range of Titanium grades, as melted or with different types of finishing. These ingots can be produced in several diameters and weights.

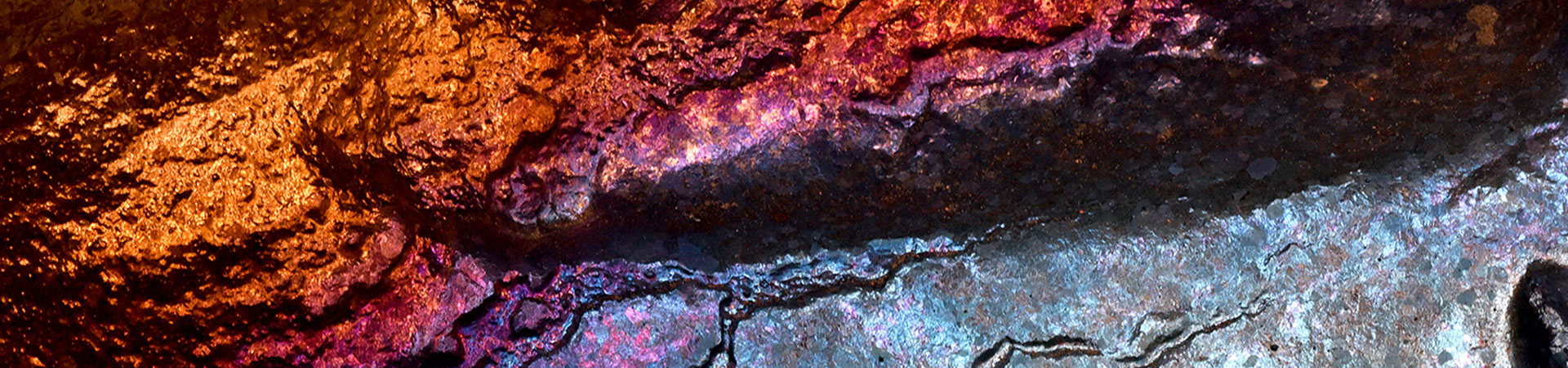

High Voltage

Power Line of 130.000 volts.